Quality Management for Electronics & Electrical Engineering

References from Electronics and Electrical Engineering

QM Solutions for Electronics & Electrical Engineering

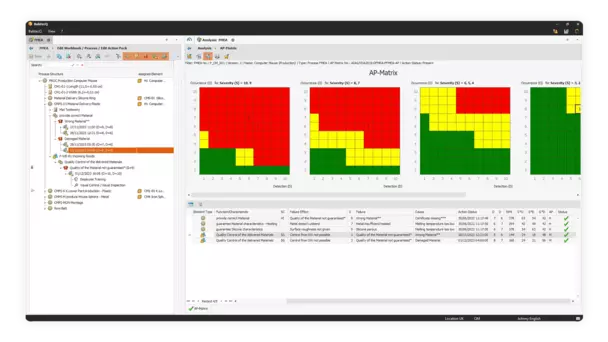

Failure Mode and Effects Analysis (FMEA)

You create FMEAs in BabtecQ on the basis of the proven seven steps.

In the electronics and electrical engineering industry, products are often complex systems consisting of a large number of components. A failure or malfunction of a single component can have a significant impact on the overall function of the product. With an FMEA, potential sources of error can be identified as early as the design and development phase and appropriate measures can be taken to minimize these risks.

With the FMEA in the BabtecQ QM software, you can carry out failure mode and effects analyses on the basis of standard-compliant or individual catalogs.

Control Plan

The control plan in BabtecQ is your tool for a sophisticated production control plan that leaves nothing to be desired.

The control plan plays an essential role in ensuring product quality: a control plan defines clear standards, procedures and requirements for the manufacturing processes to ensure that every vehicle produced meets the specified quality criteria.

With the dedicated module in BabtecQ, you can digitally map your production control plans.

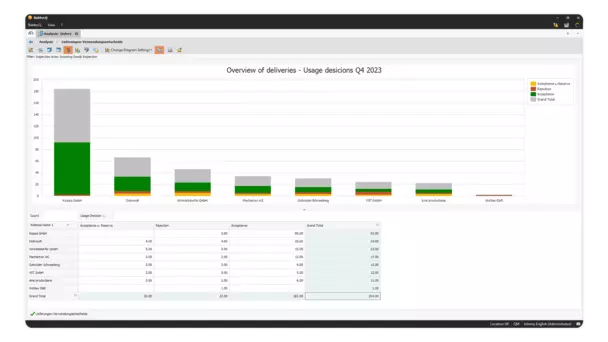

Incoming Goods Inspection / Outgoing Goods Inspection

If you detect errors in an incoming goods inspection, you can trigger a supplier complaint directly thanks to the comprehensive modules in BabtecQ.

Electronic components and devices must meet precise specifications in order to function properly. Incoming goods inspections and outgoing goods inspections ensure that the supplied components and manufactured products meet quality standards and show no deviations.

By using the incoming goods inspection / outgoing goods inspection in the BabtecQ QM software, you minimize the time and effort required for inspections and free up time for tasks that arise in your own production.

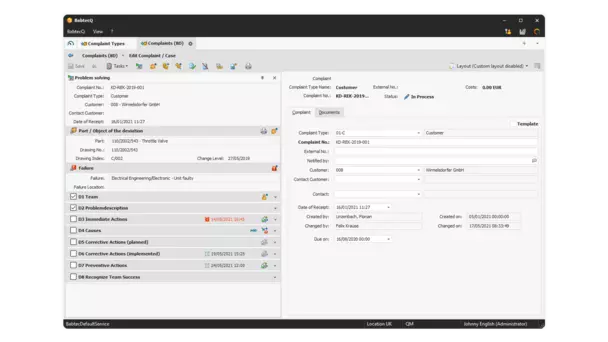

Complaints Management

Complaints management in BabtecQ makes it easier for you to consistently evaluate complaints.

Complaints management provides valuable data on defects and faults that occur in products. This data can be used to identify recurring problems and initiate continuous improvement measures in the production process or in product development.

Take the opportunity to optimize your own processes through complaints and claims. Complaints management in BabtecQ supports you in this.

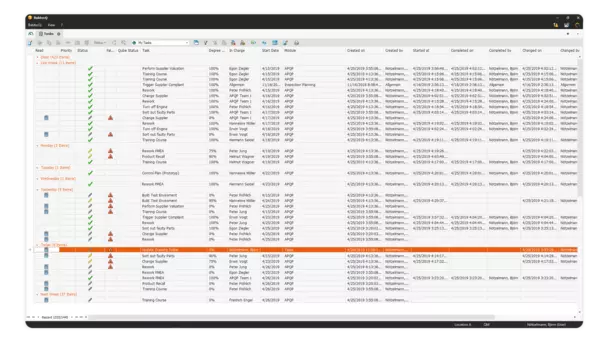

Task Management / Action management

Whether immediate actions implemented, remedial actions introduced or preventive measures: In the dialog for processing an action, you document relevant information in a central location.

Electronic products are often manufactured in complex production processes that involve a large number of steps and components. Errors can easily creep in and lead to quality deviations. Effective action management makes it possible to quickly identify and analyze deviations and initiate appropriate corrective actions.

Use the task and action management of the BabtecQ QM software to centrally manage and track your tasks and actions.

As Precise as a Microchip – Write a Success Story with QM Software from Babtec.

Switch to Success: The Relevance of Quality Management

A Contribution to the Success Story – QM

- Product safety and reliability: In the electronics and electrical engineering industry, safety and reliability are paramount. Quality management ensures that products meet the required safety standards and function reliably.

- Precision and accuracy: Electronic components and systems require a high degree of precision and accuracy. Quality management ensures that manufacturing processes and inspection procedures are optimized to meet exact specifications, maximizing product performance.

- Interoperability and compliance: Electronic devices and components often need to interact with other systems or devices. Quality management ensures that products comply with the relevant norms and standards to ensure seamless interoperability.

- Innovation and competitiveness: The industry is heavily influenced by innovation and technological progress. Effective quality management enables companies to develop, test and launch new technologies faster, increasing their competitiveness.

- Traceability and failure handling: Electronic products often consist of complex assemblies. Quality management ensures that every step in the manufacturing process is documented. This enables efficient traceability in the event of quality problems or failures.

Guidelines & Standards

Numerous components of an electrical or electronic device must be optimally interlocked to function under safe conditions for users or operators. To ensure both safety and functionality, numerous standards and guidelines provide orientation. Examples include:

- ISO 9001 for an effective quality management system

- IEC 60038 with international standards for rated voltages to ensure consistency and comparability of electrical systems

- IEC 60950-1 with safety requirements for information technology equipment

- IEC 61010-1 with safety requirements for electrical equipment for measurement, control and laboratory use

- IEC 61508 related to the safety integrity of electrical, electronic and programmable electronic safety-related systems

- IEC 60204-1 with safety requirements for electrical equipment of machines

- IEC 60364 dealing with electrical installation standards and requirements to ensure electrical safety in buildings

- EN 61000 series dealing with the electromagnetic compatibility (EMC) of electrical and electronic equipment to ensure that they function correctly in an electromagnetically noisy environment