Quality Management in the Automotive Industry

References from the Automotive Industry

QM Solutions for Automotive Suppliers

APQP Project Management

Plan and monitor your projects with APQP in BabtecQ – for seamless documentation and efficient project management.

Advanced Product Quality Planning (APQP) is widely used in the automotive industry. APQP helps companies to recognize changing customer requirements at an early stage and integrate them into the product development process. It also promotes structured project planning and tracking, minimizing delays and unforeseen costs.

With APQP in the Babtec software, you can create project plans with all the necessary project steps. Plan, manage and track all phases of product development through to series production.

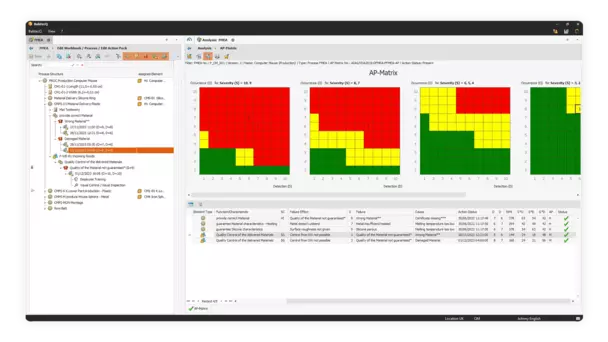

FMEA

You create FMEAs in BabtecQ on the basis of the proven seven steps.

In the automotive industry, product or process failures often have serious consequences – e.g. safety risks, recalls and reputational damage. With the help of failure mode and effects analysis, companies identify potential sources of failure, assess their impact on products and develop suitable actions to minimize risk.

Use the FMEA in BabtecQ to bundle valuable knowledge about products and processes in addition to the risk analysis.

Control Plan

The control plan in BabtecQ is your tool for a sophisticated production control plan that leaves nothing to be desired.

The control plan plays an essential role in ensuring product quality: a control plan defines clear standards, procedures and requirements for the manufacturing processes to ensure that every vehicle produced fulfils the specified quality criteria.

With the control plan in BabtecQ, you can digitally map your production control plans.

Initial Sampling / PPAP / PPF

You can manage and document your initial samples in BabtecQ in a centralized and clearly structured manner.

The aim is to guarantee the safety, performance and reliability of the vehicles. Through initial sampling, companies in the automotive industry ensure that the components meet the quality standards defined by guidelines and customer requirements.

Ensure that you only produce goods when they meet the required quality standards – initial sampling in BabtecQ supports you in this.

In-Production Inspection / SPC

In BabtecQ you can simulate inspection sequences to avoid subsequent corrections.

In-production inspections offer great added value in the automotive industry: potential defects can be recognized at an early stage and rectified immediately. This reduces the likelihood of rejects and expensive rework. The data can also be analyzed and used to identify optimization potential in the manufacturing processes.

With the in-production inspection module in the BabtecQ QM software, you can monitor product quality and control production processes using batch inspections, defect collection cards or statistical process control (SPC).

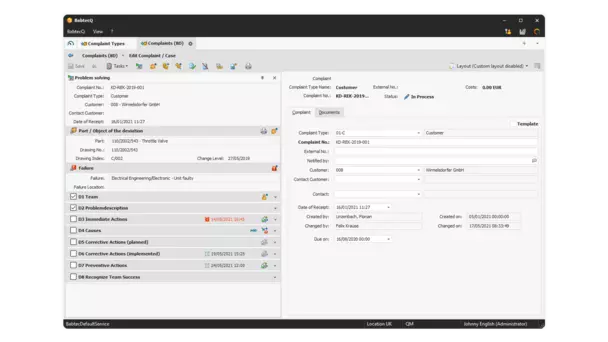

Complaints Management

Complaint management in BabtecQ makes it easier for you to consistently analyze complaints.

Complaints are a valuable source of information. By systematically analyzing complaints, companies can identify patterns that indicate recurring quality problems. They also offer the opportunity to trace products and processes – which is particularly advantageous in the automotive industry due to complex supply chains.

Take the opportunity to optimize your own processes through complaints and claims. The complaint management in BabtecQ supports you in this.

Action Management

Whether immediate actions, remedial actions or preventive actions: In the dialogue for processing a action, you document relevant information in a central location.

Series or spare parts are often produced in complex manufacturing processes that involve a large number of steps and components. Failures can easily creep in and lead to quality deviations. Effective action management makes it possible to quickly identify and analyze deviations and initiate appropriate corrective actions.

Use the task and action management of the BabtecQ QM software to centrally manage and track your tasks and actions.

In the Fast Lane – Writing a Success Story with QM Software from Babtec.

Quality on Four Wheels: The Relevance of Quality Management

A Contribution to the Success Story – QM

- Cost reduction and efficiency: An effective quality management system helps to optimize production processes and minimize failures. Considerable costs can be saved by avoiding rejects, recalls and warranty claims.

- Compliance with regulations: The automotive industry is subject to a wide range of legal regulations and standards, ranging from vehicle safety to environmental compatibility. Quality management ensures that these regulations are adhered to in order to avoid legal consequences and reputational damage.

- Safety aspects: The automotive industry manufactures products that have a direct impact on consumer safety. Quality management ensures that vehicles and their components meet the highest safety standards, minimizing accidents and potential risks.

- Complexity of the supply chain: Automotive production usually involves an extensive supply chain with various suppliers and partners. Quality management plays a crucial role in ensuring quality throughout the supply chain.

- Global production: Various components and parts are usually manufactured and brought together in different parts of the world before a vehicle is produced. A quality management system makes it possible to monitor the quality of the components, set standards and ensure that the various components fit together seamlessly.

- Technological innovation: Modern vehicles are technologically highly sophisticated. They contain complex systems and electronic components – from infotainment to autonomous driving systems. Quality management ensures that all systems function correctly.

Guidelines & Standards

Dozens of vehicles pass various roads and highways every day. The impeccable functionality of the vehicles is one of the main reasons for road safety. Directives and standards play a key role in ensuring this. Examples of this are:

- IATF 16949 with specific requirements for a quality management system for series and spare parts production in the automotive industry

- ISO 9001 for an effective quality management system

- ISO 14001 for an environmental management system that promotes environmentally conscious behavior and the introduction of more sustainable practices

- ECE regulations and UN-ECE standards with various aspects of vehicle safety, emissions, fuel efficiency and technical requirements, developed by the United Nations Economic Commission for Europe (UNECE)

- ECE directives and type approvals with technical requirements and test procedures for various aspects of vehicles including safety, emissions and electronic systems

- ISO 26262 with specific requirements for the functional safety of electrical and electronic systems in motor vehicles

- NHTSA regulations with regulations for vehicle safety and emissions relating to the US market, developed by the National Highway Traffic Safety Administration (NHTSA)