Software for Part Approval Process / PPAP / PPF

The "Part Approval Process" Module from Babtec

Deviations or errors that occur during series production always result in additional costs that could be avoided. Suppliers must therefore check and ensure that the customer's requirements for the new product and its production process are also met under realistic series production conditions. By carrying out part approval processes in accordance with PPAP (Production Part Approval Process, AIAG) or PPA (Production Process and Product Approval, VDA Volume 2) and documenting it in the form of an initial sample inspection report (ISIR), you fulfill the customer requirement to provide proof that your products are ready for series production. The comprehensive ISIR software offers you valuable practical support in the implementation and documentation of your inspection processes.

Efficient Approval Processes

for products and production processes

Standard-Compliant Reports

supported by AIAG and VDA 2 Templates

Targeted Integration

of drawings, inspection plans and existing part approval processes

Implement, Manage and Document Part Approval Processes Efficiently with ISIR Software

From Preparation through to Initial Sample Inspection Report

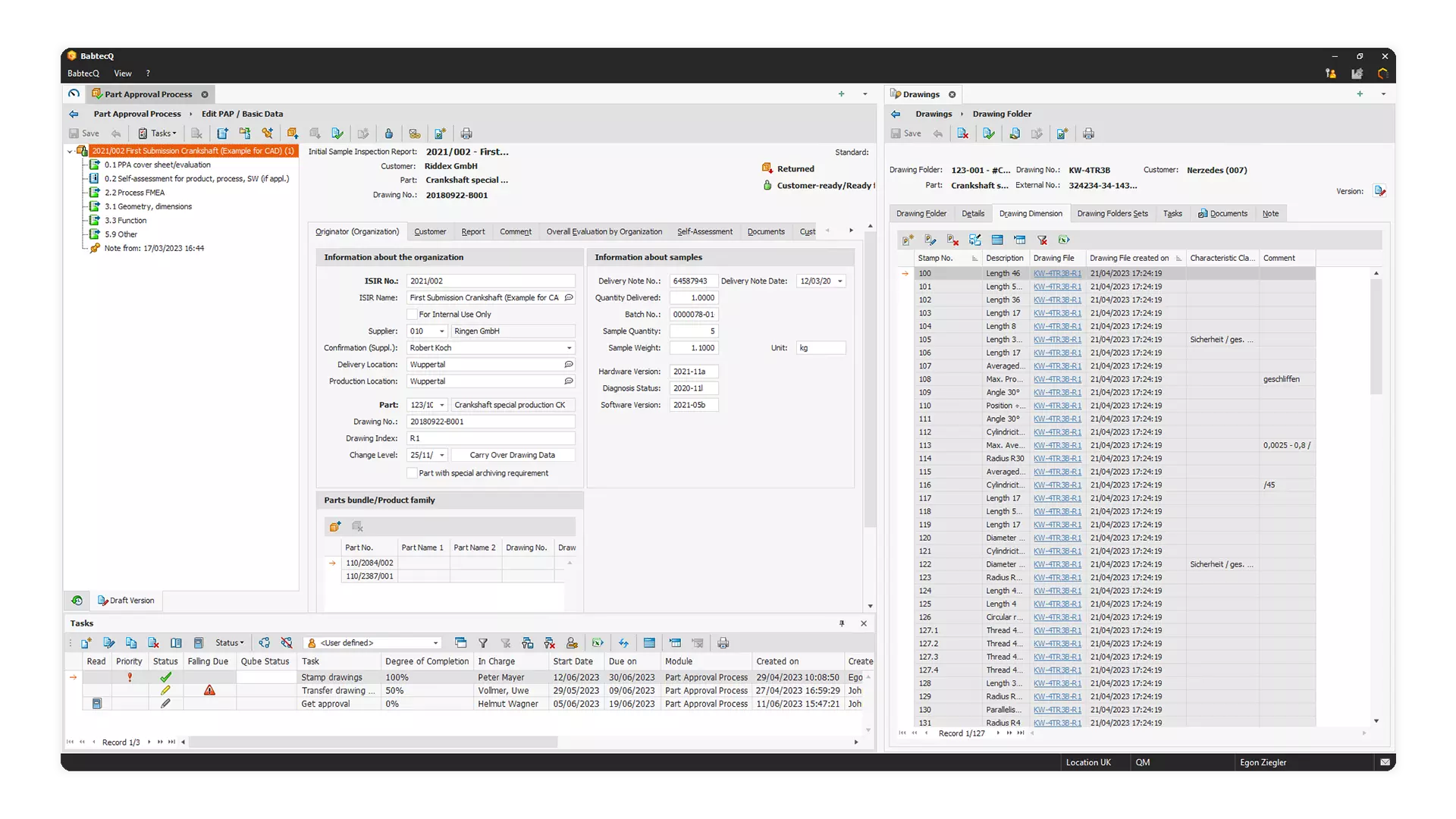

The "Part Approval Process" module provides you with comprehensive support for the effective implementation and management of your approval processes and the creation of the initial sample inspection report (ISIR) within the fully integrated Babtec software. The requirements of PPAP (Production Part Approval Process, AIAG) or Production Process and Product Approval (PPA, VDA Volume 2) are supported. You either derive the characteristics of the initial sample part from the specifications of a CAD drawing or transfer them from other part approval processes, from inspection plans or data in Q-DAS format. From the inspection result, you create the ISIR directly in the software. If, on the basis of the ISIR submitted, the customer gives the approval for series production, does this serve the supplier as proof that the delivered products meet the customer's quality requirements.

Features & Functions of the Initial Sample Inspection Report Software

Standardize ISIRs Software-Supported

If several part approval processes in a similar form become necessary, you don’t have to start from scratch each time: In the Babtec software, you can store your own templates for part approval processes. If required, you can quickly refer to these. A customer-specific template can, for example, contain the specific evidence required by the customer or by an industry standard.

Planning and Executing Part Approval Processes

Access CAD drawings, characteristic information in Q-DAS format and existing part approval processes or inspection plans. In this way you can use and import existing data in order to define all characteristics that are necessary for generating the ISIR as part of PPAP or PPA.

During the initial sample inspection, you record the measured values and inspection results to be documented for each initial sample part – conveniently via an interface to the inspection equipment used of by importing it from a file in Q-DAS format, which was provided directly by the measuring machine used, for example. If necessary, additional information can be recorded for each measured value, such as the nest or batch number.

Manage Proofs, Evaluations and Approvals

You can manage initial sample approvals clearly from the supplier or customer perspective. Decisions that have been made are recognizable in the ISIR software at a glance thanks to the intuitive visualization with symbols and colors. The documented results can be summarized in the required ISIR according to PPAP (AIAG) or PPA (VDA Volume 2) and made available in report form.

Use the Advantages of Integration for Efficient Part Approval Process According to PPAP or PPA

Further documents, which are required as part of the part approval process and have been created based on data from other modules of the Babtec software, can be merged with the ISIR. If required, you can refer directly to process FMEAs, control plans, gauge capability tests, etc. in the ISIR software. Versioning of the documents allows you to always have an overview of the different processing statuses. Tasks that arise in the course of the part approval process can be directly assigned to the responsible persons in the central task and action management. This gives you a powerful initial sample inspection report software that supports you in reducing the usually considerable effort involved in carrying out extensive part approval processes according to PPAP or PPA.

Companies That Already Rely on Babtec

From Medium-Sized Family Businesses to International Corporations

Your Contact to Us

Would you like more information about our products, perhaps even in a personal consultation? Then please feel free to contact us!

You can reach us at the following times:

Monday–Thursday, 9:00 a.m.–4:00 p.m.

Friday, 9:00 a.m.–1:00 p.m.

Are you already using our software and need support? Then please contact our support team directly.

Our colleagues will be happy to help you during our service hours:

Monday–Friday, 8:00 a.m.–5:00 p.m.