Quality Management in the Plastics Industry

References from the Plastics Industry

QM Solutions for the Plastics Industry

CAD Integration

With CAD integration in BabtecQ, you can easily provide the CAD drawings of your machines and systems for quality management processes.

CAD drawings provide detailed technical information about products and serve as a reference for expected product features. Their integration into quality processes enables accurate planning of manufacturing processes and material requirements to ensure product quality and efficiency.

CAD integration in the BabtecQ QM software enables you to integrate existing CAD drawings into your quality processes.

Initial Sampling / PPAP / PPF

You can manage and document your initial samples in BabtecQ in a centralized and clearly structured location.

With initial sampling, you ensure that the first parts produced fulfil the required quality and specifications. If you identify failures during this process, you can rectify them before mass production begins. Initial sampling therefore minimises the likelihood of production interruptions and expensive rework.

Ensure that you only produce goods when they meet the required quality standards – initial sampling in BabtecQ supports you in this.

In-Production Inspection / SPC

In BabtecQ you can simulate test sequences to avoid subsequent corrections.

Production inspections offer great added value in the plastics industry: potential defects can be recognized at an early stage and rectified immediately. This reduces the likelihood of rejects and expensive rework. The data can also be analyzed and used to identify optimization potential in the manufacturing processes.

With the in-production inspection function in the BabtecQ QM software, you can monitor product quality and control production processes using batch inspections, defect collection cards or statistical process control (SPC).

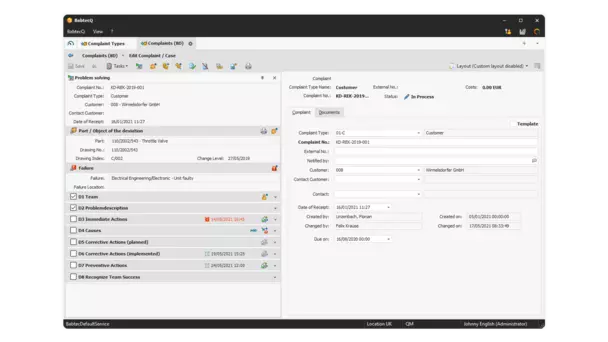

Complaints Management

Complaint management in BabtecQ makes it easier for you to consistently analyze complaints.

Complaints management has a positive influence on many factors: product quality, customer loyalty, risk management and increased efficiency. By learning from complaints, processes can be optimized and the likelihood of repeated failures reduced.

The BabtecQ QM software supports you with complaint management to minimize financial losses due to recalls.

Incoming Goods Inspection / Outgoing Goods Inspection

With BabtecQ, you can create clearly structured, efficient inspection sequences and support the correct execution of the inspection with visual assistance.

Incoming goods inspections enable the evaluation of supplier quality. Outgoing goods inspections ensure that products meet the requirements before dispatch. They are key components of successful quality management to ensure consistent and high-quality production.

However, inspections usually involve a lot of effort. BabtecQ supports you with your incoming goods inspection / outgoing goods inspection and enables you to carry out the inspections efficiently.

From Raw Material to Master Mould – Writing a Success Story with QM Software from Babtec.

Form & Function in Harmony: The Relevance of Quality Management

A Contribution to the Success Story – QM

- Product consistency and quality: In the plastics industry, the consistency and quality of the products manufactured is of crucial importance. Quality management ensures that the plastic products meet the defined specifications and standards.

- Material variability: Plastics can be available in different variants and qualities. Quality management makes it possible to select the right materials that meet the requirements of the specific application. This prevents product defects due to material incompatibility or failure.

- Environmental impact: The industry is under increasing pressure due to the environmental impact of plastic waste. Quality management can help ensure that plastic products are durable, reusable and recyclable.

- Safety aspects: Quality management ensures that plastic components fulfil the necessary safety requirements and do not pose any potential risks to end users.

- Innovation and research: The plastics industry is strongly characterized by technological progress and innovation. Quality management supports this process by accompanying the development of new materials, manufacturing processes and production methods. This allows innovative products to be brought to market more quickly without compromising quality.

Guidelines & Standards

The plastics industry often produces individual components that are used in end products manufactured in other sectors – for example in cars, medical products or packaging for consumer goods such as food. Companies in the plastics industry are therefore subject to numerous regulations and requirements that essentially relate to other sectors. Examples include

- ISO 9001 for an effective quality management system

- ISO/TS 16949 with specific requirements for a quality management system for series and spare parts production in the automotive industry

- IATF 16949 with specific requirements for international automotive manufacturers and suppliers

- ISO 13485 with specific requirements for the manufacture of medical devices – and plastic components used for this purpose

- ISO 14001 for an environmental management system that promotes environmentally conscious behaviour and the introduction of more sustainable practices

- ISO 22000 with specific requirements for food safety management systems