The Supply Chain Act

In order to comply with the requirements of the Supply Chain Act, the use of QM software is highly advisable.

The Supply Chain Act applies in Germany since January 1, 2023.

It provides for the gradual binding of companies to human rights due diligence across national borders.

Implementation is not only mandatory, but also an opportunity.

By acting responsibly along the global value chain, you create quality that inspires.

Take action today to prepare for the future.

Our QM software BabtecQ supports you in meeting the legal requirements of the Supply Chain Act.

The Key Points of the Supply Chain Act

Relevant Aspects at a Glance

- The Supply Chain Act will come into force on January 1, 2023.

- This concerns German companies with 1,000 or more employees within Germany.

- In terms of due diligence, companies will then be responsible for their own company and their suppliers upstream in the supply network.

- Violations could result in fines and exclusion from public tenders for up to three years.

QM Software in Response to the Supply Chain Act

Normative and legal requirements have long been taken into account in quality management. Risk assessment, by means of which potential risks are detected early on, the onboarding process of a supplier and the review of his economic actions are just a few examples. Take the Supply Chain Act as an opportunity to further expand your quality management with the new legal obligations and also growing needs. Solutions to ensure that you demonstrably meet the requirements of the Supply Chain Act can be found in the precisely tailored modules of our QM software.

With audits, you can check and ensure the effectiveness of a management system in your own company or at your supplier's. It is examined whether the internal company processes as well as the requirements and guidelines comply with the standards. A structured supplier onboarding as well as regular auditing of your suppliers is an essential step to meet the requirements of a Supply Chain Act.

Effective and economically justifiable incoming and outgoing goods inspections ensure the correct handling of inspection planning and processing. Only an inspection based on sophisticated inspection plans provides certainty about the quality of the goods and minimizes the risk of a defective delivery or a complaint. The often considerable effort involved in the inspection planning and the inspection process itself can be minimized by reusing inspection characteristics once created in other inspection plans or by connecting measuring equipment and machines for automatic inspection data processing.

Complaints are extremely helpful for the production of innovative products and long-term customer loyalty when their causes are consistently analyzed and tracked. They show where action is required in the case of defective products and enable continuous improvement of products and processes on the supplier's side – so that all parties benefit from higher quality products and services.

The Supplier Cockpit is a supplier management tool that allows you to assess and classify suppliers. This helps you to identify risks early on, to develop the quality of and relationships with suppliers in a targeted manner, and to avoid additional costs caused by inadequate supplier performance. You provide the supplier with the results of the assessments and define joint actions for optimization. In this way you develop the business relationship for the benefit of all parties involved in the long term.

Babtec supports you in successfully networking with your customers and suppliers. After all, cooperation based on partnership makes it easier for you to meet the requirements of the Cupply Chain Act.

For the management of your customer and supplier network you can use the cloud-based platform BabtecQube, on which more than 4,100 companies already digitally map their quality management. Work together with colleagues and business partners on quality tasks such as goods inspections and complaints or spontaneously exchange information on quality issues. Communication in the BabtecQube is archived and is available online at all times to those involved. In this way, you can easily prove receipt of self-disclosures, certificates or complaints.

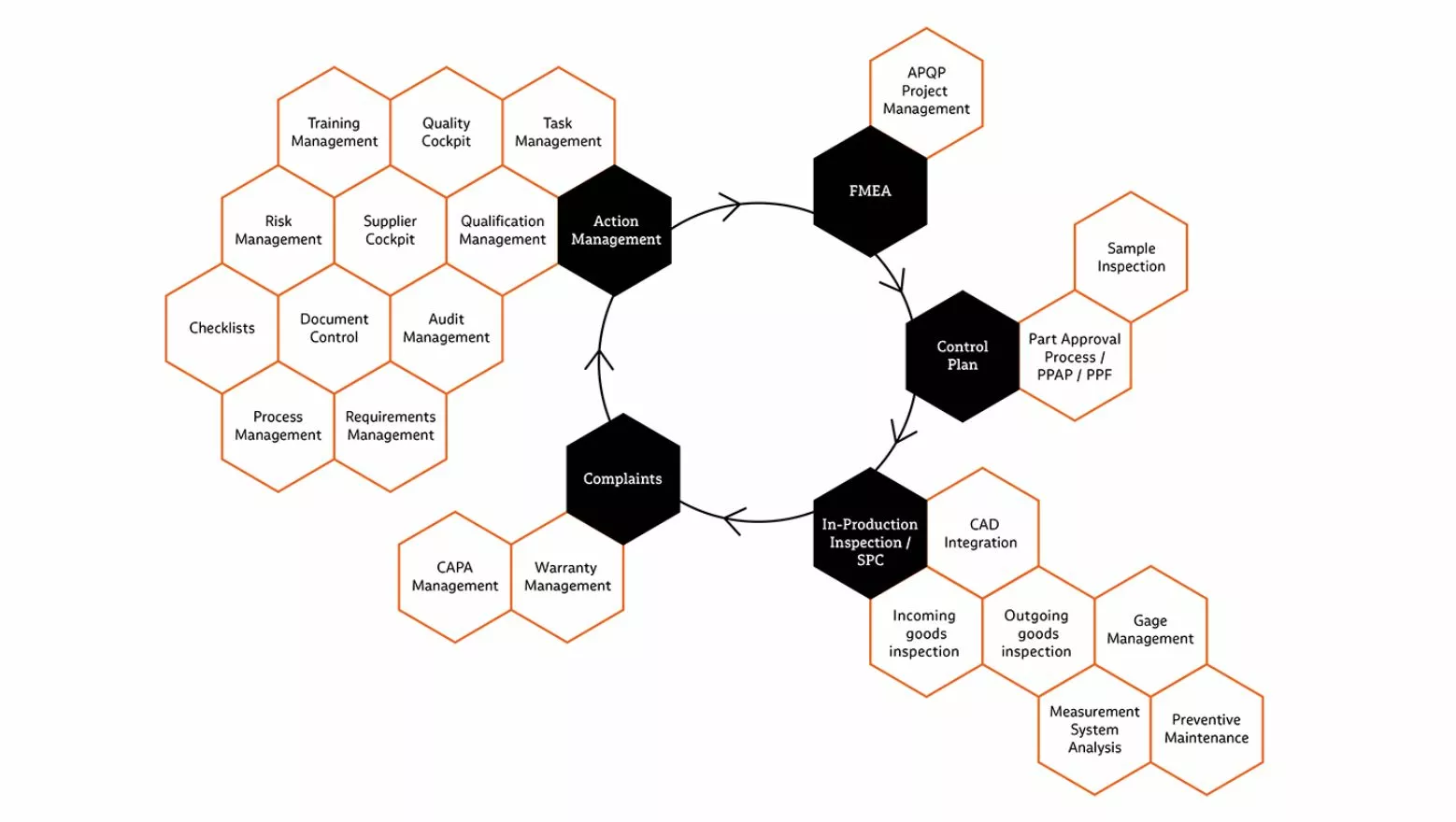

Variety of QM Modules for Your Processes

BabtecQ as an integrated CAQ software offers you a wide range of QM modules for your processes. The modules mentioned above are particularly suitable for meeting the requirements of the Supply Chain Act.

In addition, you have the option of mapping entire control loops. Captured data and information are exchanged between the numerous software modules, which is an important prerequisite for supporting your work processes. In addition, normative requirements from ISO 9001 or IATF 16949 have been among the drivers for our software development since the very beginning. The Closed Quality Loop therefore includes a variety of QM methods so that you can optimally implement your quality management system and fulfill standard requirements in the best possible way.