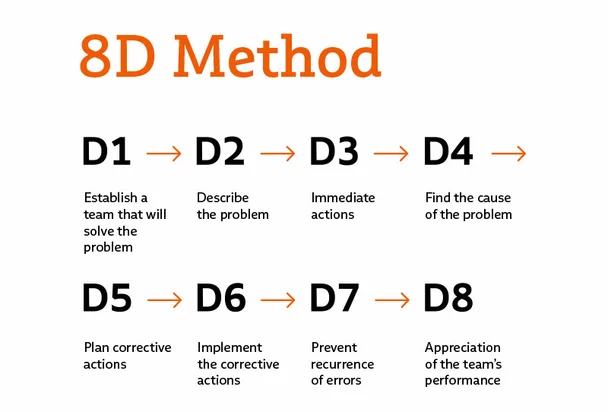

The 8D method continuously supports companies in achieving long-term goals. The quality of the products is ensured, which also minimizes error costs and increases profits. Companies can achieve these business goals precisely with the help of the 8D report by reacting quickly to complaints (immediate action) and eliminating errors at the first occurrence. From the customer’s point of view, the 8D report is also a proven means of further developing their suppliers. Not only because the absence of repetitive errors improves the relationship between customer and supplier, but also because the joint, systematic work with the 8D report allows targeted communication.

Apart from economic benefits, ecological benefits also result from the efficient handling of complaints. Today, the sustainable use of resources is more closely linked to quality than ever before; and those who act in accordance with recognized quality rules and standards act sustainably. A classic win-win-win situation: environmentally conscious companies reduce waste, conserve resources and at the same time have more satisfied customers.

Comments

No comments