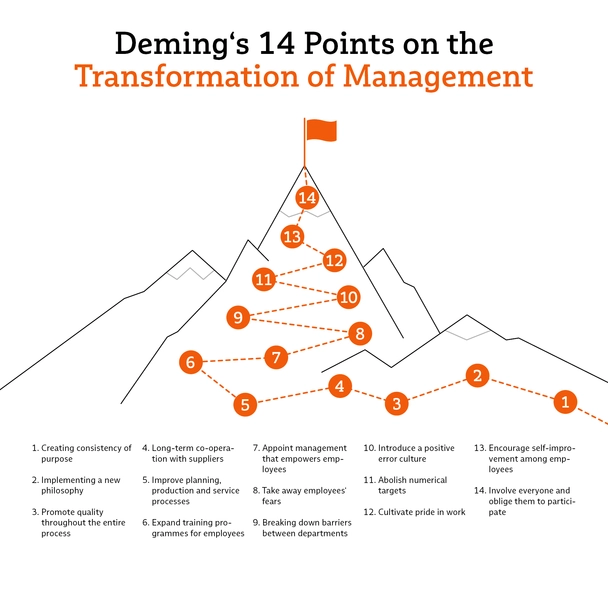

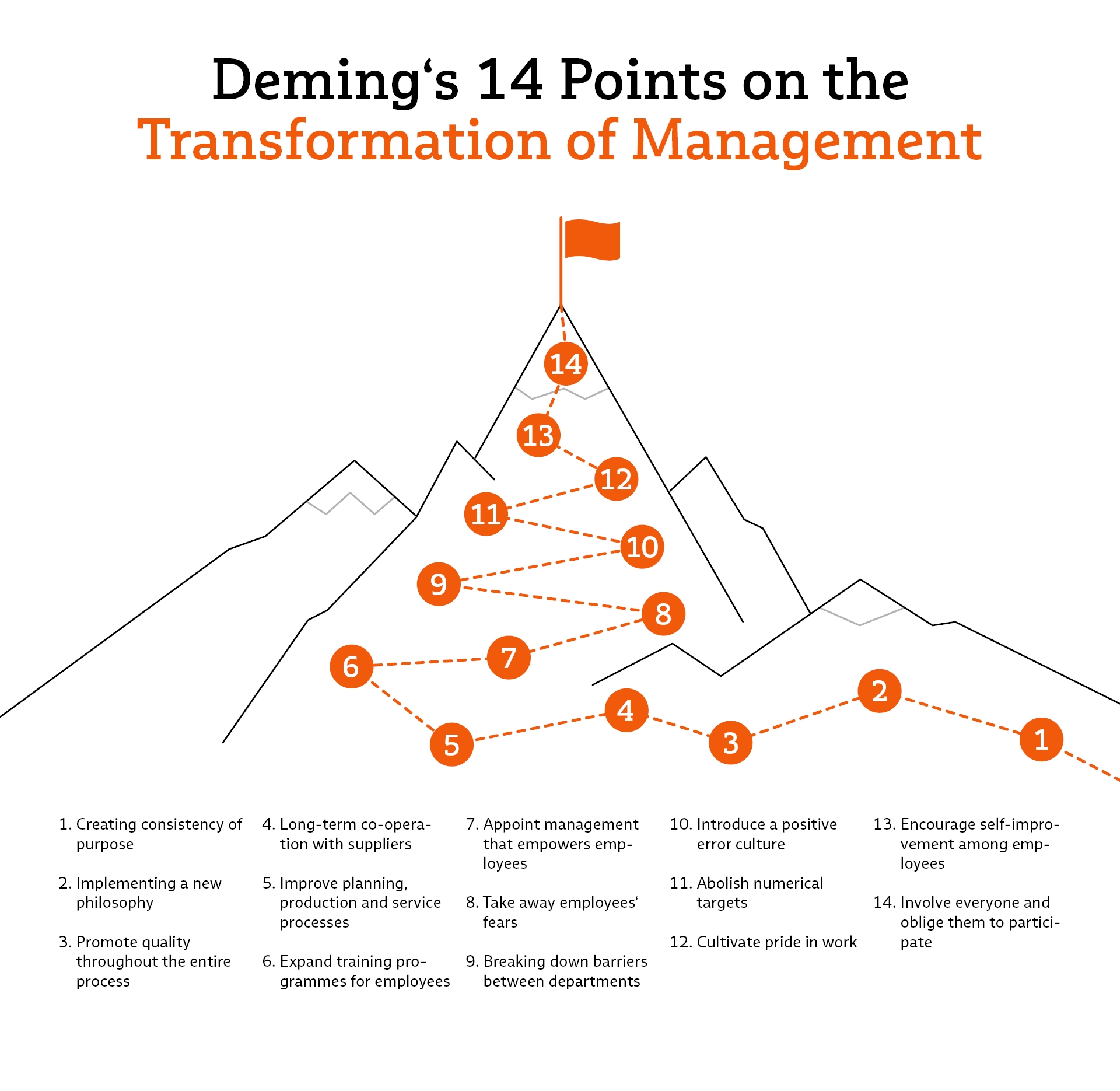

William Edwards Deming (1900-1993) spent his career studying topics such as statistics, systems thinking, and human psychology. In the process, he came up with an idea that would later make a lasting impression on the world: in order to be able to guarantee quality in the long term, it must be understood as a system goal in an organization. This can only be achieved through comprehensive quality management (Total Quality Management), in which all areas and employees are included. In addition to his scientific work, he also worked as a consultant for executives, large companies and governments. From today’s point of view, his work had a great influence on production and service companies worldwide, which redesigned their management according to his theory.

What initially sounds like a straightforward career was a major challenge for Deming at the time. In his home country, the USA, no one was initially interested in his quality ideas in the 1940s. In Japan, however, he found a more sympathetic ear: from 1950 onward, various major Japanese companies sought Deming’s advice. With his comprehensive approach, he not only focused on internal cooperation between individual departments, but also included external partners such as suppliers and customers. Deming thus made a significant contribution to the turnaround of Japan’s post-war industry and its economic rise.

Comments

No comments