While the exact PPAP procedure can vary greatly from company to company in individual areas (e.g. ordering of parts, delivery, time of sampling), five submission levels are used for all sampling processes. In these five steps, the part to be inspected is first sampled and then classified according to previously defined criteria. At the end of the process, an assessment is made which is used to decide whether the sampled part meets the requirements, needs to be improved or even requested again.

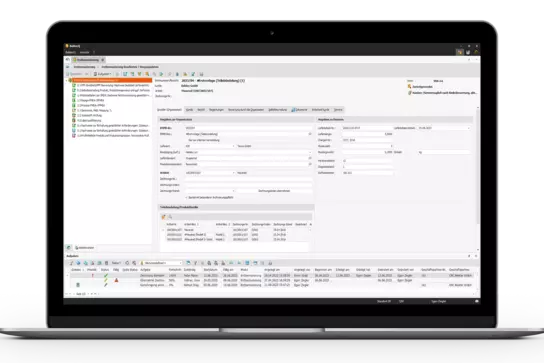

The so-called part submission warrant (PSW) is used for this purpose. The part submission warrant summarizes and documents all important information on the requirements and tests of a sample. The part submission confirmation can be understood as the cover sheet for the sampling, on which central information such as key data on the delivered product and the supplier is recorded. It also confirms that the samples presented were manufactured under complete series conditions.

Comments

No comments